Aws Cwi Fundamentals Explained

Aws Cwi Fundamentals Explained

Blog Article

What Does Aws Cwi Do?

Table of ContentsNot known Factual Statements About Aws Cwi The Best Guide To Aws CwiExamine This Report about Aws CwiNot known Details About Aws Cwi The Ultimate Guide To Aws Cwi

Have you ever before took into consideration a profession as a welding assessor? A welding assessment accreditation is not only a terrific accomplishment, it validates your capabilities in the welding market.

Ending Up Being a Licensed Welding Examiner reveals your dedication to growing within the welding sector. This qualification is one that ought to not and will certainly not be overlooked! As a CWI, you'll have the ability to take benefit of a number of different opportunities among industry specialists.

Qualified Weld Inspectors are an exceptionally useful and valuable possession for metal producers. Their existence is quite helpful for any kind of firm employing the fabricators that bring them aboard. As you might understand, welding is just one of the most complex solutions within the steel manufacture industry. The result of every welding task is extremely reliant upon specific welder skill.

Things about Aws Cwi

There's no question that CWIs assistance to support better degrees of consistency and quality to the welding divisions they manage. This article offers a short summary of the major advantages of collaborating with a metal construction company that utilizes certified weld assessors. It's not shocking that a lot of top-level sectors will require you to hire licensed welding inspectors to manage welding.

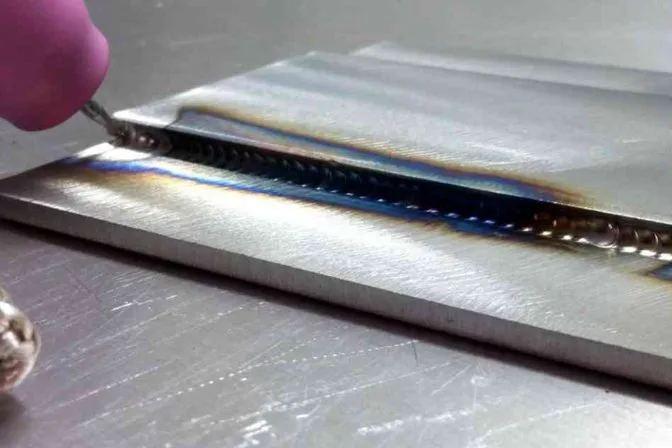

Licensed welding examiners have years of experience and thus, they comprehend the subtleties of conformity with welding codes. Following the welding procedure, CWIs can perform a series of test to examine the quality of a weld, including visual inspection, warm therapy and a hydrostatic test. Welding Inspection Agency. They can likewise make the correct modifications to the pre-weld preparation and the in-weld procedures as essential

An internal certified welding examiner will have the ability to ensure that your job is customized to all the requirements of relevant welding codes, guaranteeing its quality. Welding assessors can assess welding procedure requirements, building and welding strategies, equipment calibration and welding products. A welding inspectors ability to offer welding treatment specifications supplies the steel manufacture company a considerable side of the competitors, enabling fabricators to create article source welds that best fit individual components, as opposed to using tried-and-true welds.

How Aws Cwi can Save You Time, Stress, and Money.

As formerly discussed, a CWI is not just liable fore writing the treatments for the weld, however likewise the quality-check testing treatments. https://businesslistingplus.com/profile/awscw1w3lding/. Beyond that, welding examiners function to make certain that devices is correctly prepped for the task which welders are able to finish their welds with competence (Welding Inspection Agency). A qualified welding inspector will have had several years of experience, which a steel construction firm can leverage to make certain stellar results for all construction tasks that entail welding

This is why it's important to find a welding firm with an experienced and very trained internal qualified welding inspector on personnel. Fortunately, CAMM metals is such a company, so contact us today if you have an approaching project that calls for quality custom-made welding! It's clear that a custom steel construction vendor with internal CWIs has devoted to purchasing the top quality of its welds.

Here at CAMM Metals, after the welding portion of the job is full, we supply lots of internal solutions. These services consist of weld examination with color penetrant, acid cleaning and sprucing up of stainless steel welds.

For those clients who call for certified welds, we can license our welds to AWS D1.1 & AWS D1.6.

All about Aws Cwi

It's important to keep in mind that several companies do not constantly require welders to be accredited. The main difference is that certified welders have written documents of their examination outcomes and their efficiency is frequently kept track of with routine evaluation( s) being part of the performance record for each welder.

Prior to taking the test all PFS welders are educated, if needed, in the actual welding process that they will certainly be using and they will need to have a functioning expertise of the welding devices, welding consumable and the material to be welded. Successfully passing one test will certainly permit the welder to function on lots of sorts of manufactures Will certainly not enable him to work on all kinds of manufacture as there are credentials varies enforced for each test configuration.

Crucial variables consist of but are not limited to product kind, consumable kind, product thickness and welding position. etc. After the welder has actually completed his examination plate or pipe the weld is inspected making use of the adhering to NDE processes: Aesthetic Inspection X-Ray Fluid Penetrant Testing Sometimes, the weld is also destructively examined.

About Aws Cwi

PFS achieves this utilizing a connection record that details all welds that a welder makes. If a welder does not make use of the welding process in a 6-month duration, after that they will be requalified because procedure. The advantages to making use of an accreditation system are numerous however the significant advantages are: It validates the skill of a specific to perform according to a certified welding treatment spec (WPS) to generate an excellent weld.

Report this page